Industrial Insulation

AIM possesses extensive experience in installing insulation on all industrial mechanical and process systems.There is little to no limitation on our capabilities when it comes to industrial insulation solutions, some examples of the industrial facilities we can cater for include:

• Metal Cladding

• Power plants – coal fired and gas

• Refineries

• Manufacturing buildings

• Storage buildings

• Chemical plants

• Oxygen Plants

• Food processing plants

• Waste water and water treatment plants

• Petrochemical

• Auto manufacturing

• Plastics manufacturing

Examples of industrial systems that require insulation include any that carries or stores liquid, gas, air, or product in which the temperature of the substance being transferred or stored is impacted by the temperature of the ambient air. We insulate these mechanical systems to maintain process temperature for both hot and cold systems; to protect fluids from freezing; to provide burn protection for personnel from possible exposure to hot systems; and for sound attenuation.

Piping and duct need to be protected from both external variables and from energy loss as the result of every day use and transference.

Insulation installed correctly also protects the substrate from corrosion.

Industrial Project Highlights

Wheatstone

Clients: M&W Group Chevron

Location: Wheatstone LNG Project. Onslow WA

Duration: 5 Months

Cost: $1,300,000

Peak Manpower: 8

Hours: 6,500

LTI’s: 0

Project Overview

New LNG Production Facility for Chevron in Onslow Western Australia.

Scope of Work

Insulation and Cladding to Air Conditioning systems on twelve buildings including Control Room.

Arrium OneSteel RHF2 Upgrade

Client: McMahon Services

Location: Arrium Steel. Whyalla. SA

Duration: 2 months

Cost: $200,000

Peak Manpower: 10

Hours: 2,000

LTI’s: 0

Project Overview

Upgrade of Furnace associated Piping.

Scope of Work

Installation of Free issue materials including Insulation and overseas manufactured Cladding. Rework and modification of Cladding which did not fit or was not fit for purpose.

Dalby Bioethanol Plant

Client: Leighton Contractors

Location: Dalby Queensland

Duration: 9 months

Cost: $2,000,000.00

Peak Manpower: 20

Hours: 12,500

LTI’s: 0

Project Overview

Construction of a Bio-Ethanol production facility using Plant seeds to produce gas.

Scope of Work

Insulation and Cladding of Process Pipework, Vessels and associated Equipment.

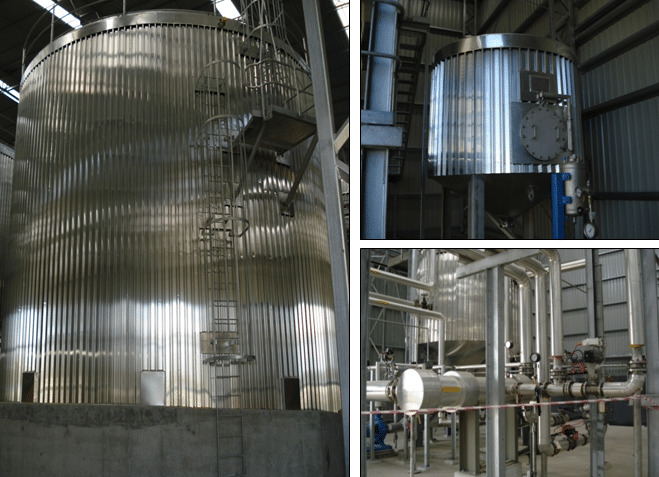

Biodiesel Production Plant

Clients: Leighton Contractors

Australian Renewable Fuels

Location: Port Adelaide SA/ Picton WA

Duration: 1 Year

Cost: $2,000,000

Peak Manpower: 20

Hours: 12,000

Project Overview

Australian Renewable Fuels constructed two facilities to convert Fats into Bio Diesel, one facility in Port Adelaide South Australia and one facility in Picton Western Australia. Each plant was identical. AIM was contracted by Leighton Contracting to perform Insulation and Cladding works on both facilities.

Scope of Work

Insulation and Cladding of Process Pipe work, Vessels and Equipment.

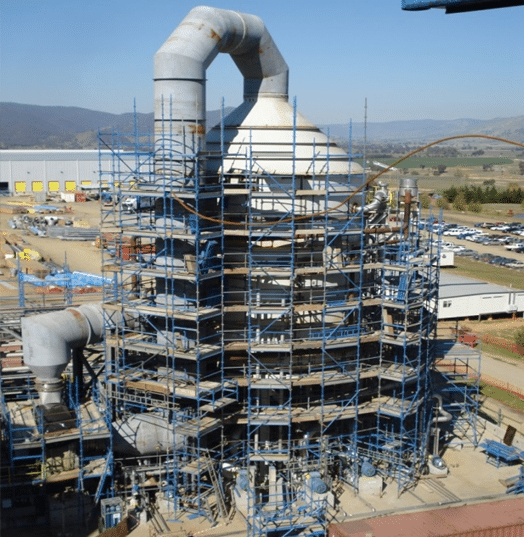

Nyrstar Port Pirie – South Australia

Client: Nyrstar

Location: Port Pirie South Australia

Duration: 2 Years

Cost: $8,700,000

Peak Manpower: 40

Hours: 40,000

LTI’s: 0

Project Overview

Port Pirie has experienced high Lead Levels in the air in and around Port Pirie for many years. This has been transmitted to having high Lead Levels in the local and surrounding community.

Nyrstar committed to spending vast amounts of money in an attempt to reducing Lead levels by purchasing the very latest equipment with new technology.

The result being the purchase of a state-of-the-art boiler, furnace, dust stripping equipment and building a new Acid Plant.

Scope of Work

Insulation and Cladding of TSL, Coal Stripping, Hot Gas Duct, Hot Gas Fan, ESP, ECT and Acid Plant.

Visy- NSW

Client: Visy

Location: Tumut NSW

Duration: 5 Months

Cost: $4,700,000

Peak Manpower: 54

Hours: 30,000

LTI’s: 0

Project Overview

The client installed a new Paper manufacturing production facility in Parallel to the existing facility. The project was delivered as a “Brown Fields Project” thus co-operation and co-ordination between the existing and new facility was handled dailyto prevent any impact on the running of the existing facility.

Scope of Work

The Scope of work required insulation and cladding of multiple Vessels and Equipment together with over three kilometres of Process Piping and the installation of all scaffolding required. AIM subcontracted the scaffold works but still had full control and management.

The project required AIM to set up and on-site workshop where 100% of the cladding required was manufactured.

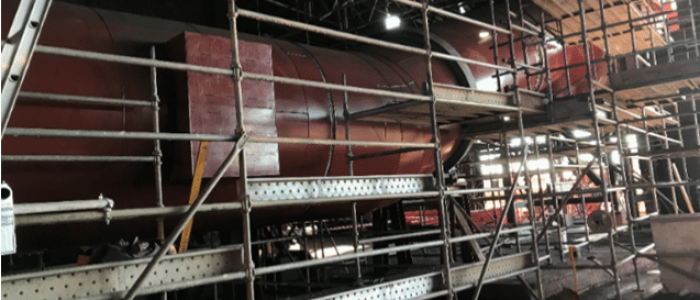

Whyalla Shutdown (pelletising plant)

Client: Port Adelaide Construction

Location: Whyalla, South Australia

Duration: 4 x weeks

Cost: $630,000

LTI’s: 0

Project Overview

Insulation and cladding of large 2m diameterduct with complicated change of direction bends together with square to round transitions.

Scope of Work

IAIM was contracted to manufacture Colourbond cladding and install 100mm thick high temperature rockwool insulation.

All duct was pinned by AIM to Australian Standards.